⇒ DOWNLOAD THE TECHNICAL SHEET

⇒ DOWNLOAD THE PREVENTIVE MAINTENANCE MANUAL

Brand: FESTO

Code: CWS COMPACT PROCESS CONTROL – BASIC VERSION

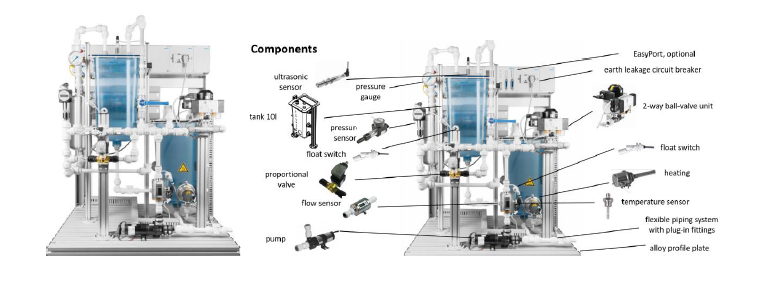

This didactic module allows students to program and carry out open-loop or closed-loop control over the most common process variables at an industrial level (temperature, level, flow rate and pressure), and allows the mixture to be homogenized in a single tank using an agitator. Equipment that allows a mixture of fluids to be prepared under certain conditions of temperature, level, pressure and flow, so it must incorporate the necessary devices that allow these variables to be regulated in real time (analog).

Features:

Type of variables to control:

Level,

Pressure,

Flow,

Temperature

Programmable Logic Controller with Display

Aluminum structure for equipment support

Water deposits

Thermometers

Flow sensors

Level sensors

Physical Dashboard

Solenoid valves

Wiring system and various cables for connection

Piping system

Data processor with the applications for the operation of the equipment.

TOPICS TO COVER BY THE STATION

Sensors and actuators

Techniques and processes

Instrumentation overview

Temperature measurement

Pressure measurement

Flow measurement

Level measurement

Includes:

Base for station

It includes a support base for the station so that an additional table is not needed for its support.

Practice Guide:

Practice guide for the teacher and students

The content of the proposal for this item is made up of the following elements:

1 1 x Compact Process Control Station -Basic FESTO Part No. C41025

2 1 x SIEMENS FESTO S15-C CONTROL KIT Part No. C43031

3 1 x MANUAL MPS PA FESTO Part No. C46001

Full Specifications

Temperature

System of Tanks and Connections: – 2 Tanks (10 L) Maximum operating temperature 65 oC. Connectors for 15 mm pipe. Polypropylene

Piping system

Quick and easy coupling (without tools)

diameter 15mm

Accessories (elbows, half-turn keys)

1000W heater

220VAC power supply

Control through a 24 VDC Relay

Operation indicator.

Pressure reservoir

Capacity 2 liters. Range: -0.95 to 16 bar

Centrifugal Pump (24 Vdc), Includes analog input control (0-10 VDC),0 – 24 VDC output, Max flow 10 l/min

Proportional Valve (24 Vdc power supply)

Analog control (0-10 VDC)

Power via 24 VDC relay

2-way pneumatic valve with rotary position display

Agitator 24VDC

Mounting Accessories.

Module sensors – Ultrasonic type level measurement. – Pressure sensor. Ceramic measurement cell sensor Measurement range: 0 – 400 mbar Output signal: 0 – 10 VDC – PT100 temperature sensor. Platinum resistance thermometer Measurement range: -50 oC to +150 oC – Float switch – Flow sensor Principle: Electromagnetic Measurement range: 0.1 – 25 l/min Output signal: 0- 10 VDC – Capacitive sensors – Float Sensors

Control system

Brand: FESTO Model: CDPX – CDPX 7″ display and control unit – Integrated switch with 2x RJ 45 Port – Integrated Soft-PLC CoDeSys V3.5 – I/O module 16 DI/DO, 4 AI/2 AO, directly on 2 SysLink cables /1 analog cable – 24 V DC connection cable – Ethernet cable RJ45, length 5 m – CoDeSys® V3 runtime software license for CDPX – CoDeSys® p.b.F V3.5 development environment

ELEMENTS INCLUDED IN THE STATION

Power supply (x1)

24 VDC source

It allows the supply of energy to all the elements of the station.

Protection elements against short circuits and overloads

Programmable logic controller (x1) – CDPX 7″ indication and control unit – Integrated switch with 2x RJ 45 Port – Integrated Soft-PLC CoDeSys V3.5 – I/O module 16 DI/DO, 4 AI/2 AO, directly on 2 SysLink cables/1 analog cable – Connection cable 24 V DC – Ethernet cable RJ45, length 5 m – Software license CoDeSys® V3 runtime for CDPX – Development environment CoDeSys® p.b.F V3.5 – Designer Studio V1.9x with client HMI – Application example with level, flow, pressure and temperature control functions for the MPS PA compact workstation –

Control Panel

Allows manual control of the system, the minimum elements to contain:

Mushroom type emergency stop button (x1)

Start button (x1)

Stop button (x1)

Reset button (x1)

Manual/automatic selector (1)

Pilot lights (x 2)

Pneumatic system

Pneumatic maintenance unit (x1)

Minimum elements to contain:

Filter regulator with water separator

Dual scale pressure gauge (bar- PSI)

pneumatic accessories

4 mm quick connect pneumatic fittings

2-way ball valve with rotary actuator

Polyurethane Plastic Hose

Note: All the accessories are compatible with the different components of the station and guarantee its optimal operation.

Valoraciones

No hay valoraciones aún.