TRANSPARENT HYDRAULIC MOBILE HYDRAULIC GROUP

BRAND: TEST INSTRUMENTS

CODE: TEHYDRO200

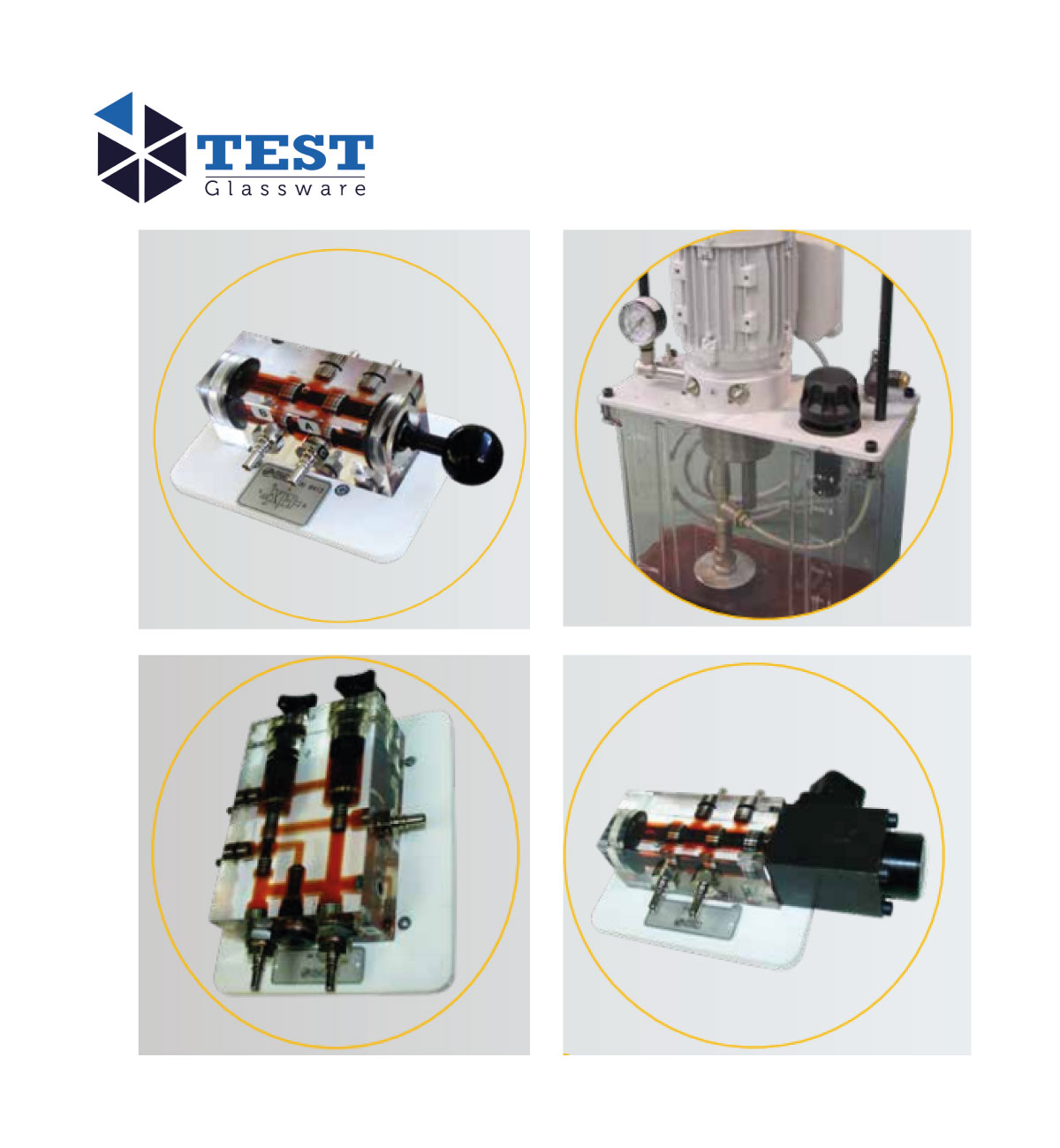

Transparent hydraulic mobile hydraulic unit, Quantity: 1, 6 liter transparent tank. -Gear pump. Q = 1l / min. -Pressure limiting valve, Max pressure: 10 bar. -3 quick connection fittings (P + 2T). -Air bubble introduction system in the circuit. -Single phase motor. Start-stop switch. Filler cap and filter. * Does not include oil drum. SAI9411 required. Single-phase motor ofapproximately 0.12 Kw Gear pump of approximately 1 l / min, A start-stop switch, the unit have a filler cap and filter, a pressure limiting valve, pressure gauge, 3 quick connect fittings and a system for introducing air bubbles into the circulating oil.

OIL DRUM – QUANTITY: 1, Colored oil drum, Special colored oil for use with transparent elements., Amount required for mobile hydraulic unit, Oil with coloring for use with transparent elements., Approximate minimum volume 1 gallon.

COMPOSITION FOR TRANSPARENT HYDRAULIC EXPERIMENTATION – QUANTITY: 1, All hydraulic elements must incorporate self-sealing quick connect fittings.Double acting cylinder – Quantity: 1, Double acting cylinder with approximately 58mm stroke.In a prismatic transparent methacrylate body and with industrial metal parts inside. Base plate with 2 self-sealing male plugs, ø20 / ø10 x 58mm stroke., Max pressure: 10bar

Manual distribution valve 4/2 – Quantity: 1, Manual actuation and spring recovery., 10 bar maximum pressure, In prismatic transparent methacrylate body and with parts, industrial metal inside, On a base plate with 4 self-sealing male plugs.

Pressure limiting valve, direct control – Quantity: 1,Allows you to set the maximum pressure value at the inlet, Pressure limiter (ball) with direct control. Manual adjustment by rotary knob, 10 bar maximum pressure. In prismatic transparent methacrylate body with parts industrial metal inside, On base plate with 2 self-sealing male plugs.

Non-return valve – Quantity: 1, It allows the passage of oil in one direction only., 10 bar maximum pressure, In prismatic transparent methacrylate body and with parts, industrial metal inside., On a base plate with 3 self-sealing male plugs.

Manually adjustable flow regulating valve – Quantity: 1. Opens or closes the oil passage by means of a lever drive, Two-way, needle, two-way flow throttle valve., Manual adjustment by rotary knob, Maximum pressure 10 bar, In prismatic transparent methacrylate body and with parts, industrial metal inside., On base plate with 2 self-sealing male plugs.

Set of 10 hoses – Quantity: 1, Set of 10 transparent polyurethane hoses., 10 bar maximum pressure, Lengths:

6 units of approximate length of 520mm.

4 units of approximate length of 350mm.

With 2 self-sealing female sockets

Distributor with 6 connections – Quantity: 1, 10 bar maximum pressure, In prismatic transparent methacrylate body, On base plate with 6 self-sealing male plugs

Cross distributor with pressure gauge – Quantity: 1, Distributor with 3 connections with pressure gauge from 0 to 16 bar. 3-connection manifold with pressure gauge, In prismatic transparent methacrylate body, On base plate with 2 self-sealing male and 1 female plugs

User and practice manual – Quantity: 1, User manual and practices, With proposed exercises and solution section with estimative measurements.

Rolling table with two-way panel. Quantity 1, Detachable rolling frame for easy transport., It has a vertical panel for work on both sides, Panel dimensions: 760x25x1150mm., It has a 1200x800mm post-forming worktop for horizontal work., At the bottom there is a 1200x600mm metal shelf that allows to house the block of drawers for storing components, the mobile hydraulic unit, etc, It rests on 4 wheels, 2 with brakes and high load power., Overall dimensions: 1200x800x1700 mm, The workstation must allow simultaneous work on each side of the panel. The components must be industrial and consist of a prismatic transparent methacrylate body that allows viewing the interior of the components. Each component must be mounted on a fixing plate to be able to insert the components into the work panel. The structure must be made of extruded aluminum with 8.5 mm grooves.